-

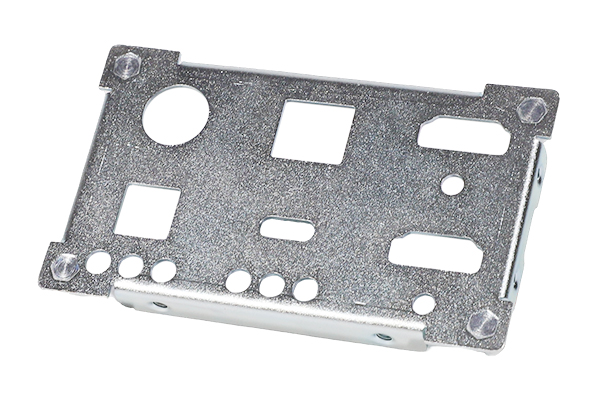

Case K0201090066100

K0201090066100

Send Email Details

① Laser Cutting for Material Preparation: A total of 5 Bystronic Diener 4000w laser cutting machines are used for cutting materials.

② Deburring: Handheld pneumatic flat grinders are employed for removing burrs.

③ Counterboring: A total of 4 Xihu-brand drilling machines are used for counterboring holes.

④ Pressing for Step Difference: A 1.2-meter-long EKO bending machine is used for pressing to create step differences.

⑤ Bending: The same 1.2-meter-long EKO bending machine is also used for bending operations.

⑥ Riveting: Corresponding rivet molds are loaded into a total of 4 riveting machines for riveting.

⑦ Powder Coating: Handheld spray guns are used for powder coating.

⑧ Packaging: Packaging is performed according to specifications, with FQC conducting a full inspection before boxing.

⑨ Shipment: Products are stamped and stored in the warehouse after passing the QA inspection. -

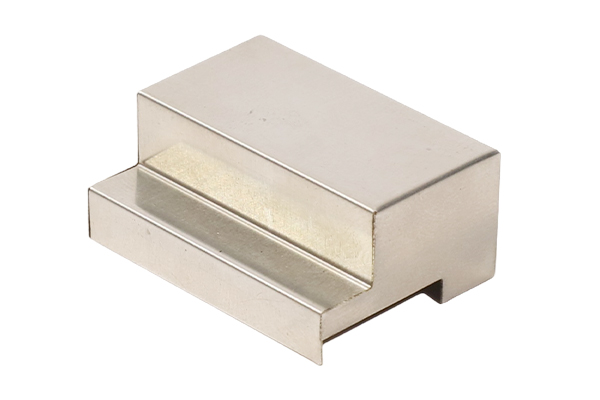

Sheet Metal K0201090053100

K0201090053100

Send Email Details

① Laser Cutting for Material Preparation: Material preparation involves using 5 Bystronic Dinon 4000w laser cutting machines.

② Deburring: Deburring is done using a handheld pneumatic flat grinding machine.

③ Flanging and Tapping: The corresponding flanging molds are used for this process.

④ Bending: The EKO bending machine with a length of 1.2 meters is used for bending.

⑤ Blue Zinc Plating: This process is outsourced.

⑥ Riveting: The corresponding rivet molds are loaded into the riveting machines. There are a total of 4 riveting machines.

⑦ Packaging: After FQC inspection according to packaging specifications, the products are packed into boxes.

⑧ Shipment: After QA inspection, the products are stamped and stored in the warehouse. -

Sheet Metal K0201090054100

K0201090054100

Send Email Details

① Laser Cutting for Material Preparation: Material preparation involves using 5 Bystronic Dinon 4000w laser cutting machines.

② Deburring: Deburring is performed using a handheld pneumatic flat grinding machine.

③ Bending: The bending process utilizes an EKO bending machine with a length of 1.2 meters.

④ Riveting: The corresponding rivet molds are loaded into the riveting machines, with a total of 4 riveting machines in use.

⑤ Powder Coating: A handheld spray gun is used for powder coating.

⑥ Packaging: After FQC inspection according to packaging specifications, the products are packed into boxes.

⑦ Shipment: After QA inspection, the products are stamped and stored in the warehouse for shipment. -

Sheet Metal K0201090055100

K0201090055100

Send Email Details

① Laser Cutting for Material Preparation: Material is cut using Bystronic Dinon 4000w laser cutting machines.

② Deburring: Deburring is performed using a handheld pneumatic flat grinding machine.

③ Bending: The bending process employs an EKO bending machine with a length of 1.2 meters.

④ Riveting: The process involves loading corresponding rivet molds into riveting machines, with a total of 4 riveting machines in use.

⑤ Powder Coating: Powder coating is applied using a handheld spray gun.

⑥ Packaging: Packaging is done according to packaging specifications after FQC inspection and the products are then boxed.

⑦ Shipment: After QA inspection, the products are stamped and stored in the warehouse for dispatch. -

Sheet Metal K0201090057100

K0201090057100

Send Email Details

① Laser Material Cutting: Material cutting is done using 5 Bystronic Dinon 4000w laser cutting machines.

② Deburring: Deburring is performed with a handheld pneumatic flat grinder.

③ Bending: Bending is done using an EKO bending machine with a length of 1.2 meters.

④ Packaging: After FQC inspection according to packaging specifications, the products are packed into boxes.

⑤ Shipment: After QA inspection, the products are stamped and stored in the warehouse for dispatch. -

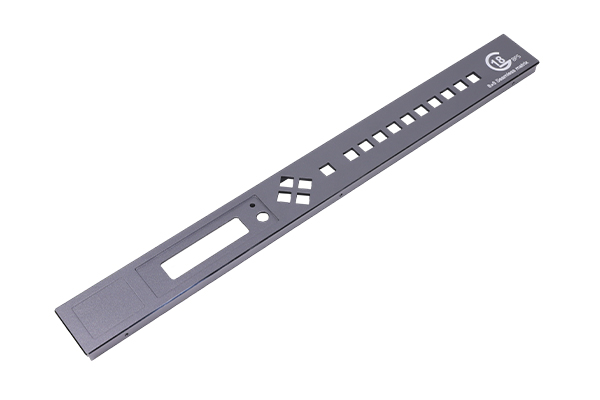

Sheet Metal K0201090061100

K0201090061100

Send Email Details

① Laser Cutting for Material Preparation: Material preparation involves the use of 5 Bystronic Dynamec 6600w laser cutting machines.

② Deburring: Deburring is done using handheld pneumatic grinding machines.

③ Machining: This process is outsourced.

④ Riveting: Riveting is performed using corresponding rivet molds loaded into a total of 4 riveting machines.

⑤ Sandblasting and Oxidation: This process is outsourced.

⑥ Polishing for High Gloss and Chamfering: This process is outsourced.

⑦ Silkscreen Printing: Silkscreen printing uses Marabu ink.

⑧ Packaging: Packaging follows the packaging specifications, with FQC inspecting all items before boxing.

⑨ Shipment: QA inspects and stamps the products before they are warehoused for shipment.