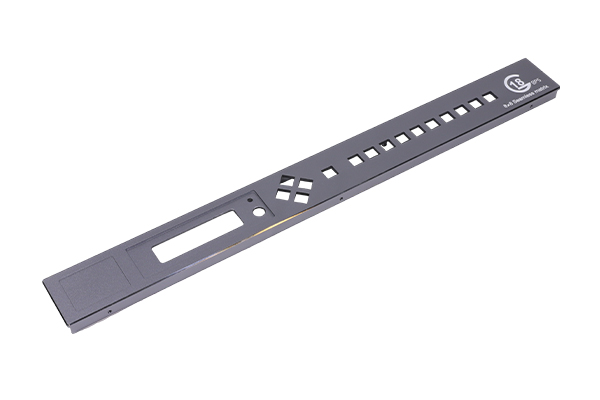

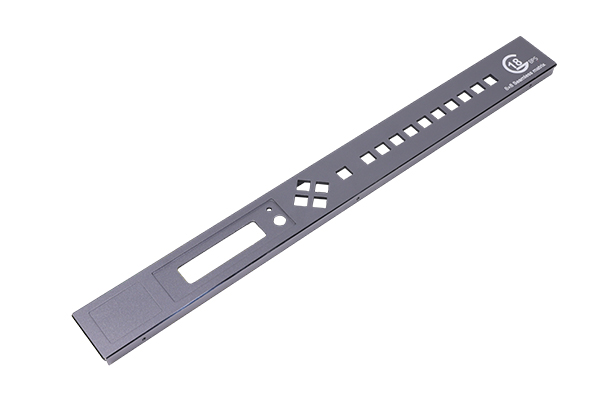

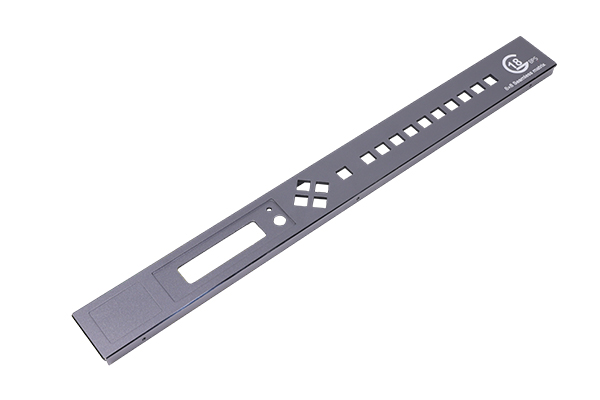

Sheet Metal K0201090061100

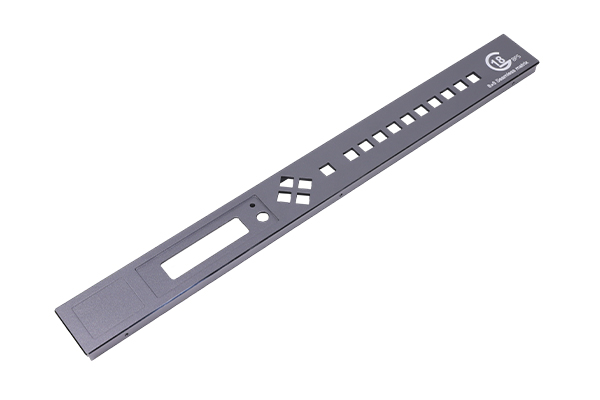

K0201090061100① Laser Cutting for Material Preparation: Material preparation involves the use of 5 Bystronic Dynamec 6600w laser cutting machines.

② Deburring: Deburring is done using handheld pneumatic grinding machines.

③ Machining: This process is outsourced.

④ Riveting: Riveting is performed using corresponding rivet molds loaded into a total of 4 riveting machines.

⑤ Sandblasting and Oxidation: This process is outsourced.

⑥ Polishing for High Gloss and Chamfering: This process is outsourced.

⑦ Silkscreen Printing: Silkscreen printing uses Marabu ink.

⑧ Packaging: Packaging follows the packaging specifications, with FQC inspecting all items before boxing.

⑨ Shipment: QA inspects and stamps the products before they are warehoused for shipment.

-

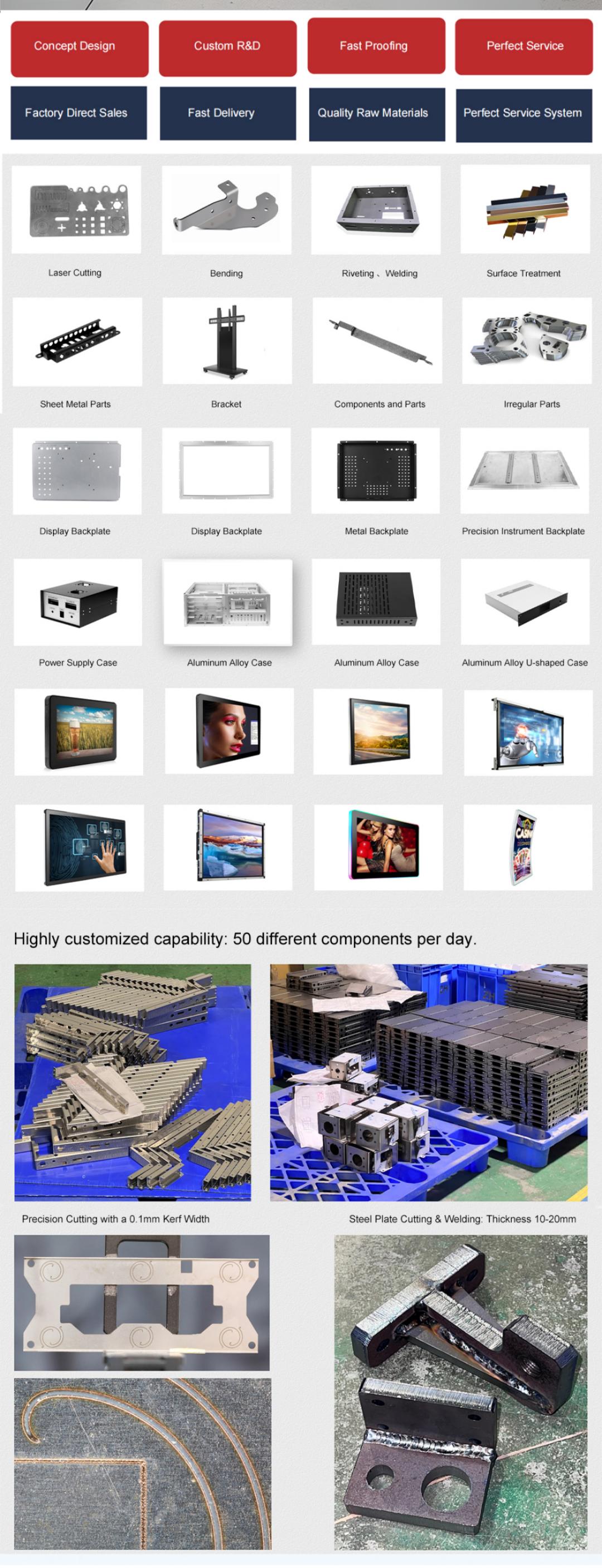

Processing Technology

1.Laser Cutting: Material cutting is done using Bystronic Dineng 6600w laser cutting machines (alternatives include 1500w, 3000w, two 4000w models, and another 6600w model), totaling 5 Bystronic Dineng laser cutting machines.

2.Deburring: Deburring is performed using handheld pneumatic flat grinders (alternatives include handheld sanders, handheld electric flat grinders, and vibratory deburring tools).

3.Machining: This process is outsourced for the machining of straight and deep holes.

4.Riveting: Riveting is done using corresponding rivet molds loaded into riveting machines (alternatives include Haiji and Hage brand riveting machines), totaling 4 riveting machines.

5.Sandblasting and Oxidation: This process is outsourced for sandblasting with 150# grit and oxidation treatment to achieve IPOD gray color.

6.High-gloss Chamfering: This process is outsourced for chamfering the edges.

7.Silkscreen Printing: Silkscreen printing is done using Marabu brand ink.

8.Packaging: Packaging is carried out according to packaging specifications (surfaces are wiped with alcohol, packaging is done according to SOP instructions, and labels are affixed to outer boxes) after FQC (Final Quality Control) full inspection.

9.Shipment: After QA (Quality Assurance) inspection, the products are stamped and stored in the warehouse.

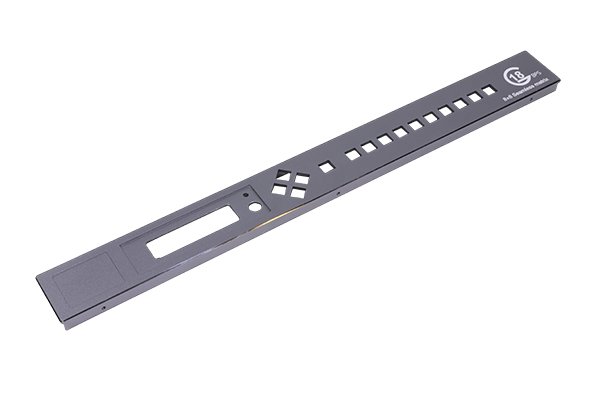

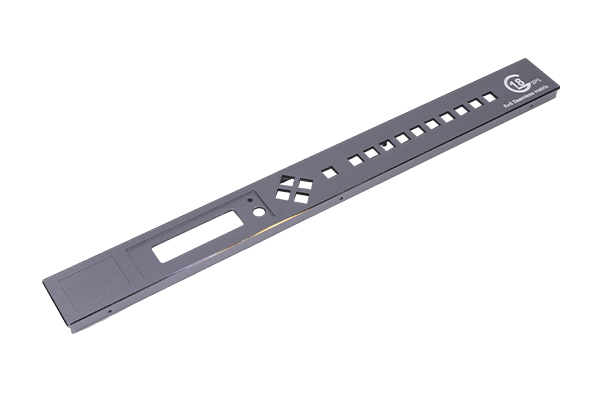

Detail Display

01.Quality Raw Materials

Carefully Selected Materials, Compliant with lndustry Standards, Rust-resistant,Sturdy and Stable

02.Mature Craftsmanship

Finely Crafted with Standard Dimensions,Smooth Surface, Attractive Appearance,and Excellent Strength

03.Rigorous Quality Control

Multiple Manufacturing Processes Detailed Control at Every Level.Strict Quality Inspection,Sturdy and Practical

04.Custom Processing

Our experienced team offers design and technical support, providing you with one-stop service for customized production according to your drawings and samples.