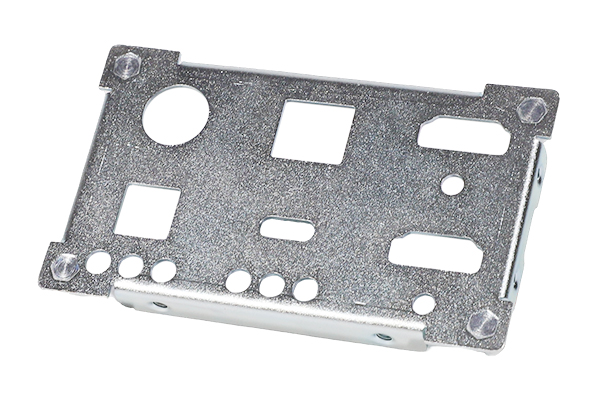

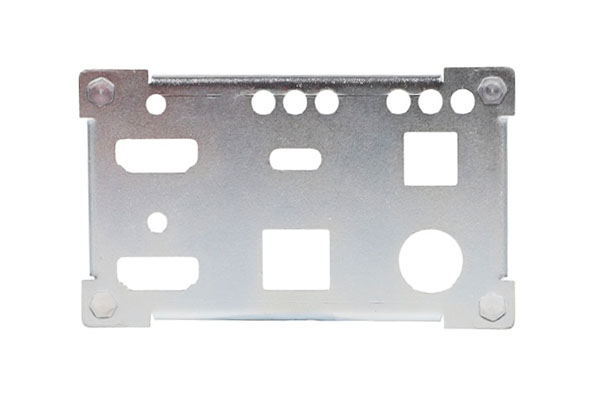

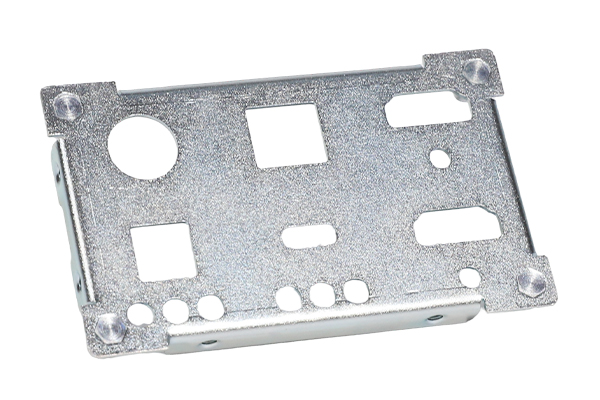

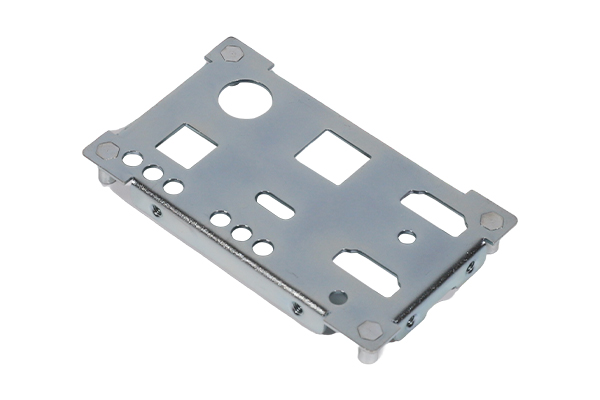

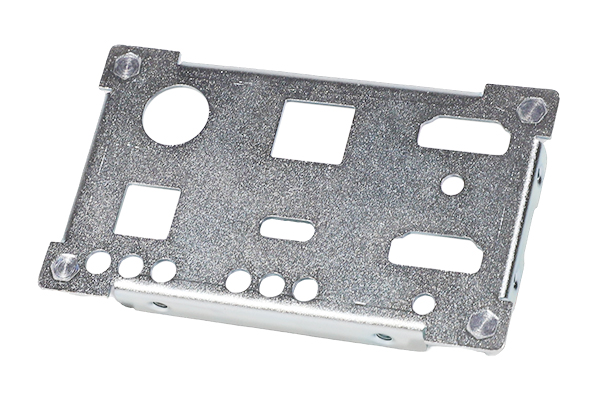

Sheet Metal K0201090053100

K0201090053100① Laser Cutting for Material Preparation: Material preparation involves using 5 Bystronic Dinon 4000w laser cutting machines.

② Deburring: Deburring is done using a handheld pneumatic flat grinding machine.

③ Flanging and Tapping: The corresponding flanging molds are used for this process.

④ Bending: The EKO bending machine with a length of 1.2 meters is used for bending.

⑤ Blue Zinc Plating: This process is outsourced.

⑥ Riveting: The corresponding rivet molds are loaded into the riveting machines. There are a total of 4 riveting machines.

⑦ Packaging: After FQC inspection according to packaging specifications, the products are packed into boxes.

⑧ Shipment: After QA inspection, the products are stamped and stored in the warehouse.

-

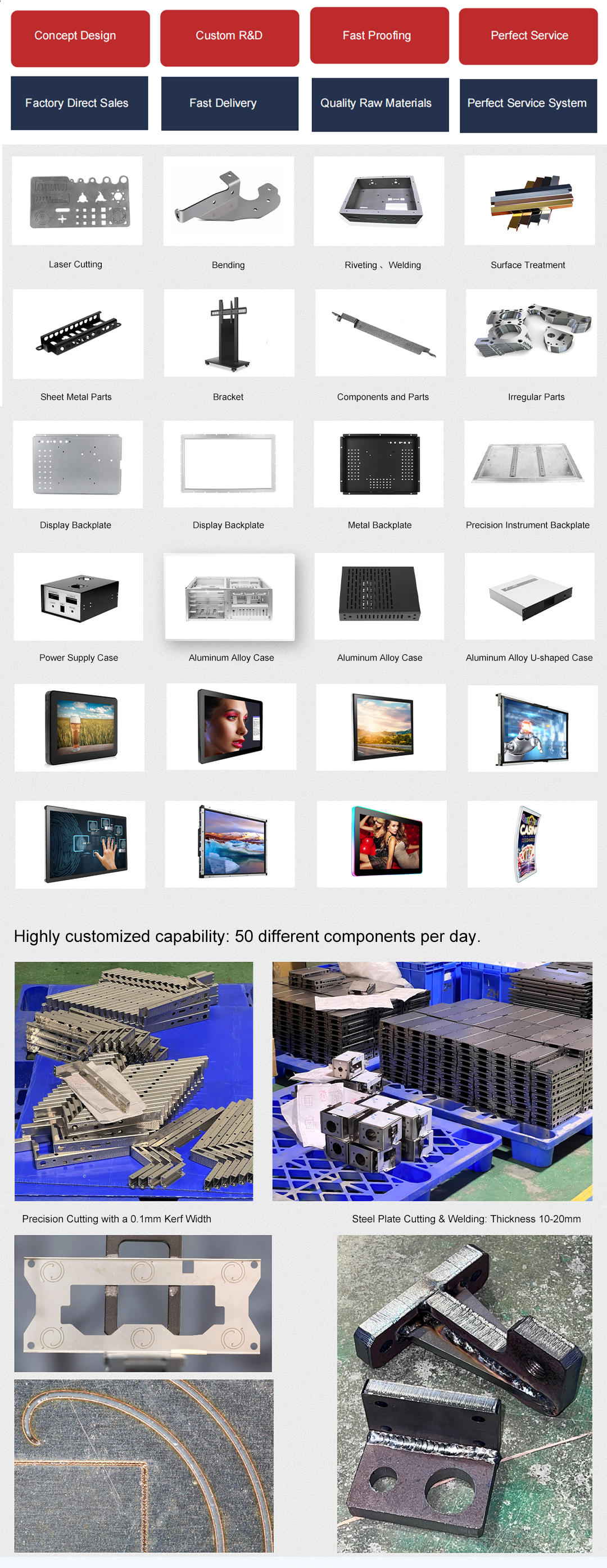

Processing Technology

1.Laser Cutting: Material cutting using Bystronic Dineng 4000w laser cutting machines (alternatives: 1500w, 3000w, two 4000w machines, 6600w), totaling 5 Bystronic Dineng laser cutting machines.

2.Deburring: Deburring using handheld pneumatic flat grinders (alternatives: handheld grinding machines, handheld electric flat grinders, vibratory deburring machines).

3.Flanging and Tapping: Using corresponding flanging molds (riveting presses).

4.Bending: Bending using a 1.2-meter-long EKO bending machine (alternatives: 4 EKO bending machines, Belgian LVD brand bending machines with processing lengths of 0.2 meters, 1.2 meters, 1.5 meters, and 3.0 meters respectively, processing accuracy up to 0.05mm-0.02mm, plus two Estun bending robots with maximum loads of 20kg-45kg, suitable for mass production).

5.Blue Zinc Plating: This process is outsourced (electroplating with color zinc).

6.Riveting: Riveting using corresponding rivet molds loaded into riveting presses (alternatives: Haiji, Hage brand riveting presses), totaling 4 riveting presses.

7.Packaging: Packaging according to packaging specifications (surface wiping with alcohol, packaging according to SOP instructions, labeling outer boxes) after FQC full inspection.

8.Shipment: Stamping and warehousing after QA inspection.

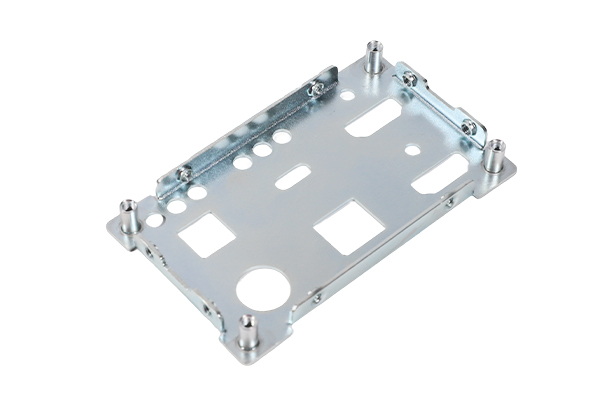

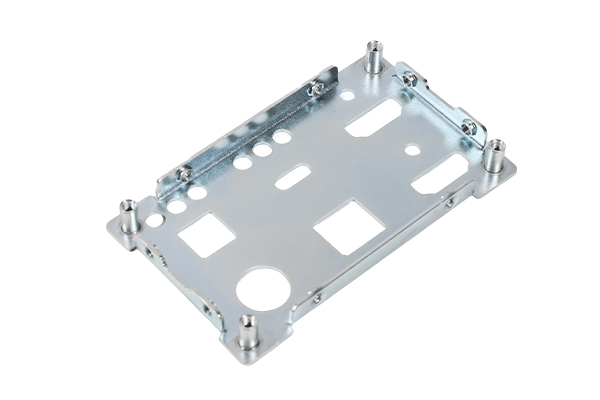

Detail Display

01.Quality Raw Materials

Carefully Selected Materials, Compliant with lndustry Standards, Rust-resistant,Sturdy and Stable

02.Mature Craftsmanship

Finely Crafted with Standard Dimensions,Smooth Surface, Attractive Appearance,and Excellent Strength

03.Rigorous Quality Control

Multiple Manufacturing Processes Detailed Control at Every Level.Strict Quality Inspection,Sturdy and Practical

04.Custom Processing

Our experienced team offers design and technical support, providing you with one-stop service for customized production according to your drawings and samples.