Case K0201090044100

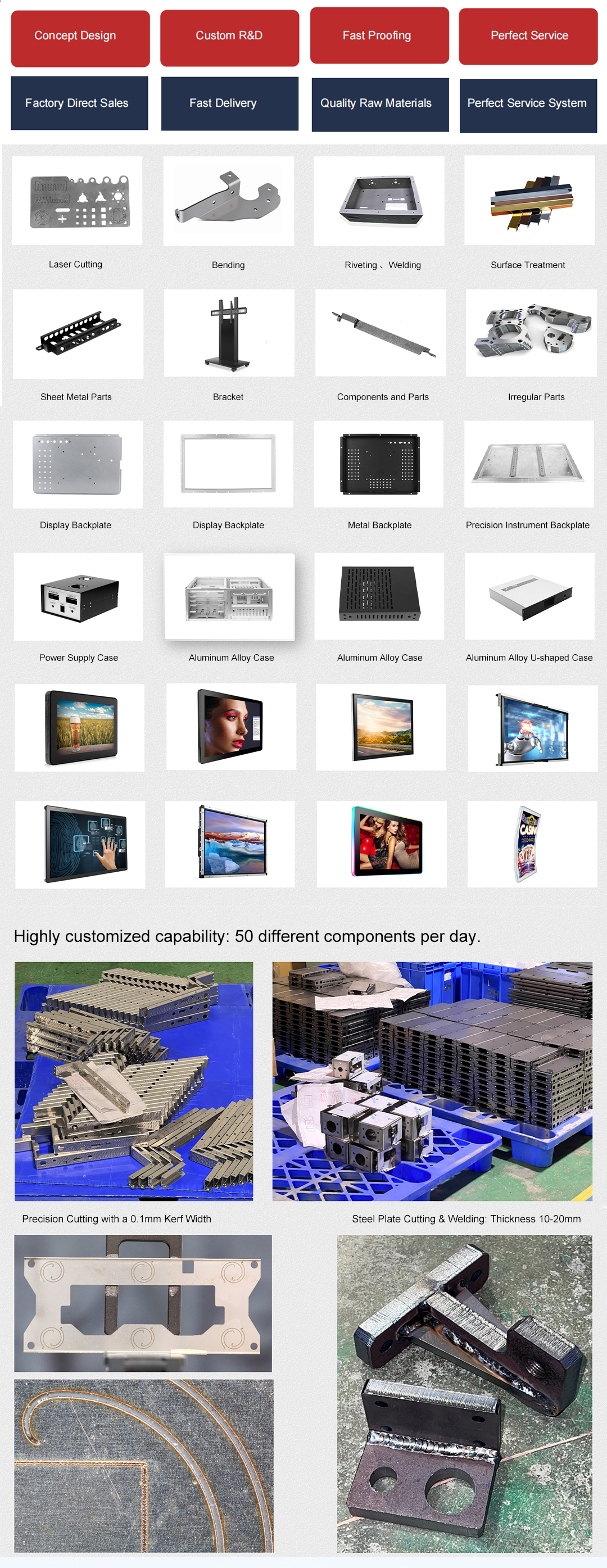

K0201090044100① Laser Cutting for Material Preparation: A total of 5 Bystronic Diener 4000w laser cutting machines are used for laser cutting.

② Deburring: Handheld pneumatic flat grinders are used for deburring.

③ Bulge Formation: Special bulge molds are used for creating bulges.

④ Flanging and Tapping: Corresponding flanging molds are used for this process.

⑤ Bending: A 1.2m EKO bending machine is used for bending.

⑥ Welding: A total of 5 laser welding machines are used for welding.

⑦ (Note: This step is a repetition of step ⑤. If it's intended to list a different bending process, please provide details. For now, I'll assume it's a mistake and won't translate it separately.)

⑧ Riveting: Corresponding rivet molds are loaded into riveting machines, with a total of 4 riveting machines available.

⑨ Powder Coating: Handheld spray guns are used for powder coating.

⑩ Packaging: Packaging is performed according to specifications, with FQC conducting a full inspection before boxing.

⑪ Shipment: Products are stamped and stored in the warehouse after inspection by QA.

-

Processing Technology

1.Laser Cutting: Material cutting is performed using Bystronic Diener 4000w laser cutting machines (alternatives include 1500w, 3000w, two 4000w units, and 6600w), totaling 5 Bystronic Diener laser cutting machines.

2.Deburring: Handheld pneumatic flat grinders are used for deburring (alternatives include handheld grinders, handheld electric flat grinders, and vibratory deburring machines).

3.Boss Forming: A dedicated boss forming mold is used with a hydraulic press.

4.Flanging and Tapping: Corresponding flanging molds are used with riveting machines.

5.Bending: Bending is done using a 1.2m EKO bending machine (alternatives include 4 EKO machines and Belgian LVD brand bending machines capable of processing product lengths of 0.2m, 1.2m, 1.5m, and 3.0m; processing accuracy can reach 0.05mm to 0.02mm; additionally, there are two Estun bending robots with a maximum load capacity of 20kg to 45kg, suitable for mass production).

6.Welding: Laser welding is used (alternatives include Panasonic argon arc welding and two 2000w laser welding machines), totaling 5 welding machines.

7.[Note: This step is repeated; it should be omitted or combined with step ⑤ if it represents the same process with different machines or specifications.]

8.Riveting: Corresponding rivet molds are loaded into riveting machines (alternatives include Haiji and Hager brand riveting machines), totaling 4 riveting machines.

9.Powder Coating: Handheld spray guns (Swiss Gema brand) are used, with ovens including conveyor belt ovens and batch ovens.

10.Packaging: Packaging is done according to packaging specifications (surface wiping with alcohol, packaging following SOP instructions, and labeling the outer box), with FQC performing full inspection before boxing.

11.Shipment: After inspection by QA, products are stamped and stored in the warehouse.

Detail Display

01.Quality Raw Materials

Carefully Selected Materials, Compliant with lndustry Standards, Rust-resistant,Sturdy and Stable

02.Mature Craftsmanship

Finely Crafted with Standard Dimensions,Smooth Surface, Attractive Appearance,and Excellent Strength

03.Rigorous Quality Control

Multiple Manufacturing Processes Detailed Control at Every Level.Strict Quality Inspection,Sturdy and Practical

04.Custom Processing

Our experienced team offers design and technical support, providing you with one-stop service for customized production according to your drawings and samples.